Introduction to Fire Sprinkler System Relining

Fire sprinkler systems serve as critical safety features in commercial and industrial properties. Over time, components like fire sprinkler tanks can degrade, often more than expected, due to corrosion, leaks, or general wear and tear. Traditionally, it had been believed that replacing an entire fire sprinkler system was the only option, however, relining offers a cost-effective and minimally invasive alternative.

The relining process involves a single application of an internal protective coating to tanks and pipes, retaining the existing infrastructure.

Relining restores watertight integrity, extends system lifespan, and upgrades to the latest fire safety standards. Typically, relining is completed within a week, ensuring minimal interruption to business operations.

Consider a 40-year-old fire sprinkler tank starting to leak; while replacing the system might exceed $150,000 with two weeks of downtime, relining with an internal epoxy coating can slash costs to one-third and reduce the job to just five days. This approach ensures uninterrupted production and up-to-date fire safety for staff and property.

Identifying When a Fire Sprinkler System Needs Relining

Several signs may suggest the need for relining a fire sprinkler system to prolong its functional life:

- Visible corrosion or deterioration - Flaking paint, rust staining, pinhole leaks, or sections visibly thinning are clear warnings. Steel tanks commonly exhibit corrosion after 10-15 years but choosing the right relining service can come with a 10year guarantee.

- Frequent small leaks - Persistent minor leaks suggest internal corrosion even if not visible externally. Left unchecked, small holes enlarge until tanks split or pipes rupture.

- Age and outdated components - Older systems degrade faster with outdated sealing materials, gaskets, or threaded connections prone to loosening over decades of thermal expansion and contraction.

- Freezing temperatures - Water expanding inside components during winter causes cracks and accelerated structural fatigue.

Although relining restores a fire sprinkler system’s integrity, it isn’t suitable for significantly compromised structures. For the best way to proceed, seek professional assessments following extreme weather or evidence of substantial leaks.

It’s advisable to inspect sprinkler tanks and pipes every five years and perform annual assessments of mechanical components. These assessments confirm whether tanks require replacement or are suitable for epoxy coating renewal.

Types of Fire Sprinkler Systems and Relining Solutions

There are three main types of fire sprinkler tanks suitable for professional relining:

- Steel Sectional Tanks - The most common choice, assembled from bolted panels. Internal epoxy coatings prevent corrosion for 10+ years.

- GRP Fibreglass Tanks - Seamless one-piece moulded tanks with a smooth interior surface. Optional polyurethane or vinyl ester barrier coatings provide added longevity.

- Concrete Tanks - Poured concrete walls lined with an epoxy or cementitious grout coating. Life expectancy exceeds 30 years.

Steel tanks show external signs of rust before internal corrosion causes leaks, whereas leaks in fibreglass or concrete tanks indicate breaches right through the structure. Fortunately, all three types can undergo professional relining tailored to the material and level of degradation.

Multi-layer epoxy coating system solutions provide the greatest corrosion resistance and longevity but require more drying time.

For optimal fire protection, consult with qualified professionals to pinpoint the ideal specifications for your system.

The Relining Process for Fire Sprinkler Systems

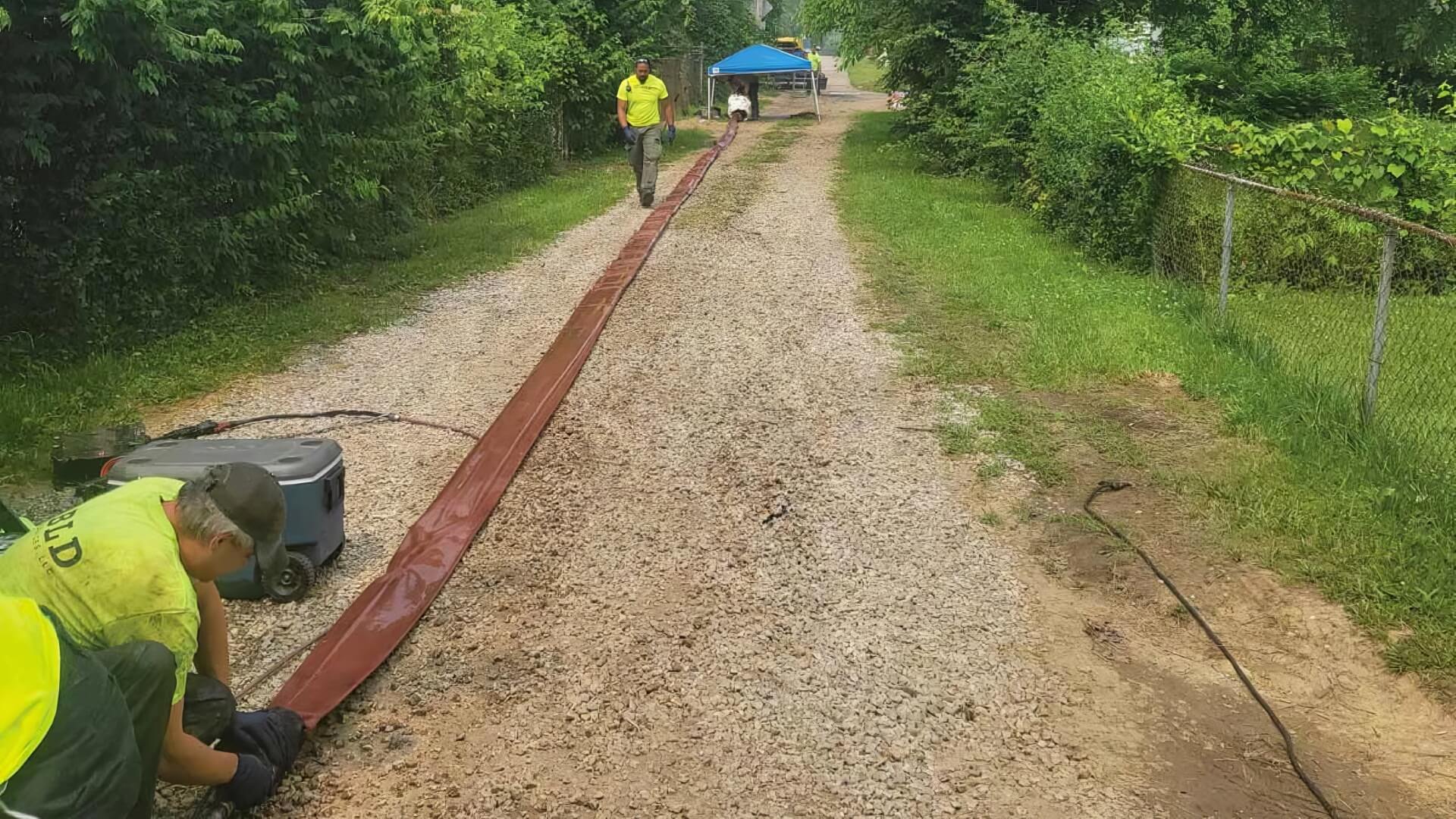

The relining process for fire sprinkler systems is a multi-step procedure performed by qualified professionals. It begins with completely draining tanks and pipes before technicians access the interior surfaces. They thoroughly clean, often employing water treatment-grade equipment, using high-pressure jets to remove loose corrosion and prepare for coating adhesion.

Specialised techniques temporarily isolate sections to ensure components remain dry during the application of liquid polymers. These include inflatable bladders inserted into pipes and custom bulkheads spanning reservoir interiors. Safety measures including fume ventilation and protective gear are essential when handling solvents and chemical liners.

Specialised water treatment-grade epoxy, polyurethane, or cementitious products are sprayed, rolled, or brushed onto surfaces. Each coat must dry fully before adding extra layers to achieve specified thickness and durability. Curing times vary from 24 hours for rapid-set cements to a week for thick glaze epoxies able to withstand decades of exposure.

After installing the durable relining barrier, the system should be reassembled with new gaskets and fittings. The system undergoes stringent testing well beyond normal operating conditions to check for leaks. Provided no defects show, it returns to reliable service protected against corrosion for years ahead while avoiding costly replacement.

Benefits of Relining vs Replacing Fire Sprinkler Systems

Relining fire sprinkler systems offers considerable advantages over replacement in terms of cost, longevity, sustainability, and convenience:

- Significant cost savings - Relining can cost as little as a quarter to a third of a complete system replacement. Relining also delivers extended system longevity, contributing to long-term savings.

- An additional 10-15 years of operational lifespan - Restored corrosion protection keeps entire systems functioning reliably years longer than ageing raw steel or pipes.

- Little business disruption - Work completes rapidly in under a week with no halt to operations. Replacement means weeks of downtime.

- Excellent durability - Epoxy and cement coatings withstand corrosion, abrasion and impacts for decades.

- Enhanced flow efficiency - Smooth interior linings improve water flow, outperforming corroded uncoated steel.

- Sustainable - Relining preserves existing system materials already in place and reduces landfill waste.

- Lower ongoing costs- Preventing pinhole leaks cuts water wastage and damage from leaks.

For instance, at the 700 square metre Watkins Distribution Centre, replacing 20-year-old fire sprinklers would have meant a $280,000 expense and a three-week period with no storage access. Instead, $92,000 spent relining the network restored full fire suppression capacity within five days and postponed replacement costs for over a decade.

Maintaining Integrity of Relined Fire Sprinkler Systems

Regular inspections and maintenance are key to maximising the longevity of relined fire sprinkler systems. Annual checks should assess internal coating condition, verifying thickness using ultrasound scanners and checking for breaches. Leaks or damage requiring repair services should be addressed promptly to prevent corrosion.

Performance testing every 5 years helps gauge the coating effectiveness for your water tank. Technicians monitor flow rates and pressure differentials, comparing results against new system benchmarks. If left untreated and deterioration impedes performance, isolated touch-ups reseal compromised sections.

As buildings expand, pipes and tanks endure stress that risks disbonding linings or cracking composites. Professionals realign components to eliminate tension while reinforcing vulnerabilities prone to future movement.

Regular inspections, functionality testing, and appropriate adjustments ensure that high-quality tank relines keep fire sprinkler systems free from leaks and corrosion over their extensive service lives. Facility managers can take pride sustaining safety infrastructure built to last yet requiring only a fraction of replacement expenditure.

Cost Savings from Relining Fire Sprinkler Systems

Relining fire sprinkler systems offers major cost savings compared to full system replacement. On average, relining costs around 30-40% of the price of installing completely new pipes and tanks. Factoring in labour, materials, operational disruptions and potential water damage, your own total savings often exceed 50%.

For instance, relining the sprinkler system of a 929 square metre warehouse, avoiding the near $350,000 expense of replacement.

This would also mean three weeks of downtime, posing a potential halt to operations. Conversely, investing $120,000 in epoxy coating restoration revitalises the system within just a week. Over a decade, choosing relining realised savings surpassing $230,000.

Small and large facilities alike realise huge cost benefits from relining. The Reliant Hotel relined their basement concrete reservoir for just 36% of replacement expense.

Dexta, a supply chain firm, saved 65% by relining their fibreglass sprinkler tank instead of opting for replacement. In both cases, expert epoxy coatings extended the systems’ lifespans by 20 years or more.

Compliance Standards for Relined Fire Sprinkler Systems

Professionally relined fire sprinkler systems must adhere to key compliance standards to guarantee safety and reliability:

Installation Standards

- AS 2118 Automatic fire sprinkler systems

- AS 2419 Fire hydrant installations

- AS 4041 Pressure piping

Materials and Performance Standards

- AS/NZS 4020: Testing of products for use in contact with drinking water

- AS/NZS 4158: Thermal spraying - Qualification tests for thermal sprayers

- NACE No. 12/AWS C2.23M/SSPC-CS 23: Specification for the Application of Thermal Spray Coatings (Metallizing) of Aluminium, Zinc, and Their Alloys and Composites for the Corrosion Protection of Steel

Inspection and Certification

- AS 1851: Maintenance of fire protection systems and equipment

- Quarterly and annual testing to AS 2941: Fixed fire protection installations

- Certificates of Lining Compliance from relining professionals

Adhering to regulatory terms and conditions ensures occupant safety, maintains insurance coverage, and helps avoid penalties. Engaging a certified sprinkler contractor, like Padstow Plumbing, is advisable to guarantee compliance with approved methods, materials, and regulatory documentation.