Identifying pipe damage through CCTV inspection

CCTV camera inspections are essential for accurately diagnosing the condition of drains and sewer pipes prior to pipe relining. A skilled technician will thoroughly assess the full extent of deterioration, pinpointing leaks, cracks, blockages or root intrusion, aiding the decision in pipe relining vs replacement. This evaluation ascertains the appropriateness of epoxy resin relining versus the need for pipe replacement.

The CCTV camera is fed through your drains sewer pipes, providing a clear internal view on a monitor. Problem areas, including the precise location and size of any holes or fractures, are clearly visible. This clear visualization ensures accurate determination of which sections can be relined rather than inferring issues from external symptoms.

In comparison to traditional excavation methods, CCTV diagnostics are far less destructive and invasive for relining pipe effectively. CCTV diagnostics enable precise, non-invasive assessment of drains, avoiding trench-digging and interior damage.

If relining is viable after CCTV inspection, our team plumbers have a precise plan for the sections needing repair, which will be carried out with meticulous attention. By thoroughly examining the internal condition first, our team can deliver targeted repairs ensuring the new relining solutions can used for long-lasting results. Pipe relining reduces costs and property damage by avoiding unnecessary pipe replacement.

How pipe relining repairs holes and leaks

Pipe relining, a trenchless repair technique, effectively repairs minor holes, cracks, and leaks without the need for excavation or complete pipeline replacement. It works by coating the inside of pipes with a smooth epoxy resin layer that seals damage and reinforces weak spots.

This less invasive method involves inserting a felt sleeve saturated with liquid epoxy resin into the pipeline, where it adheres to the interior for efficient repair. The resin permeates the sleeve, creating a firm bond with the pipe interior. As it cures, it forms a solid, jointless barrier that smooths out any rough areas and fills holes from pinhole leaks up to 50mm across.

Epoxy resin seals cracks and gaps, preventing water seepage and tree root intrusion, simplifying repairs without digging. The end result is a new pipe, renewed with enhanced flow capacity and longevity, surpassing the quality of the original pipe.

Pipe relining provides a minimally invasive alternative to the extensively disruptive drain pipe replacement. Your property remains intact and you can get your pipes restored from the inside-out without any worry about undue hassle. Relining is a quick process, with pipes typically usable again shortly after completion.

For minor holes, cracks, and leaks, the less disruptive pipe relining offers a practical solution, avoiding the mess of excavation.

The pipe relining process step-by-step

Cleaning and preparing the damaged pipe

The pipe relining process begins with thoroughly cleaning the damaged pipe to ensure a successful repair. Our technicians use high-pressure water jets to rigorously clean the inner walls of the pipe, a step crucial for successful relining.

This cleaning stage is essential to secure the lining’s adhesion to the sewer pipe surface for a successful repair. Mechanical rodders or scrubbing tools may be used for extra cleansing in cases of severe blockage. The goal is to expose the raw pipe material so it can bond with the epoxy resin.

Video inspecting the pipe condition

We conduct a detailed video inspection of your pipe’s interior, ensuring professional plumbing analysis is carried out using a remote CCTV drain camera. As the camera navigates the pipes, it pinpoints the location and severity of any damage.

Thorough CCTV diagnostics determine the pipe’s suitability for relining. If any sections are too degraded, any plumbing solution we provide will reflect the need for thoroughness and durability in our approach.

Applying protective end seals

We seal both ends of the pipe section to be relined, containing the liquid epoxy resin once inserted. Inflatable stoppers are inserted and inflated to plug the pipe openings.

These flexible seals prevent resin leakage during the curing process in your sewer system. They also enable pressure control inside the pipe section for optimal resin saturation into pipe cracks and defects.

Saturating the felt lining with epoxy resin

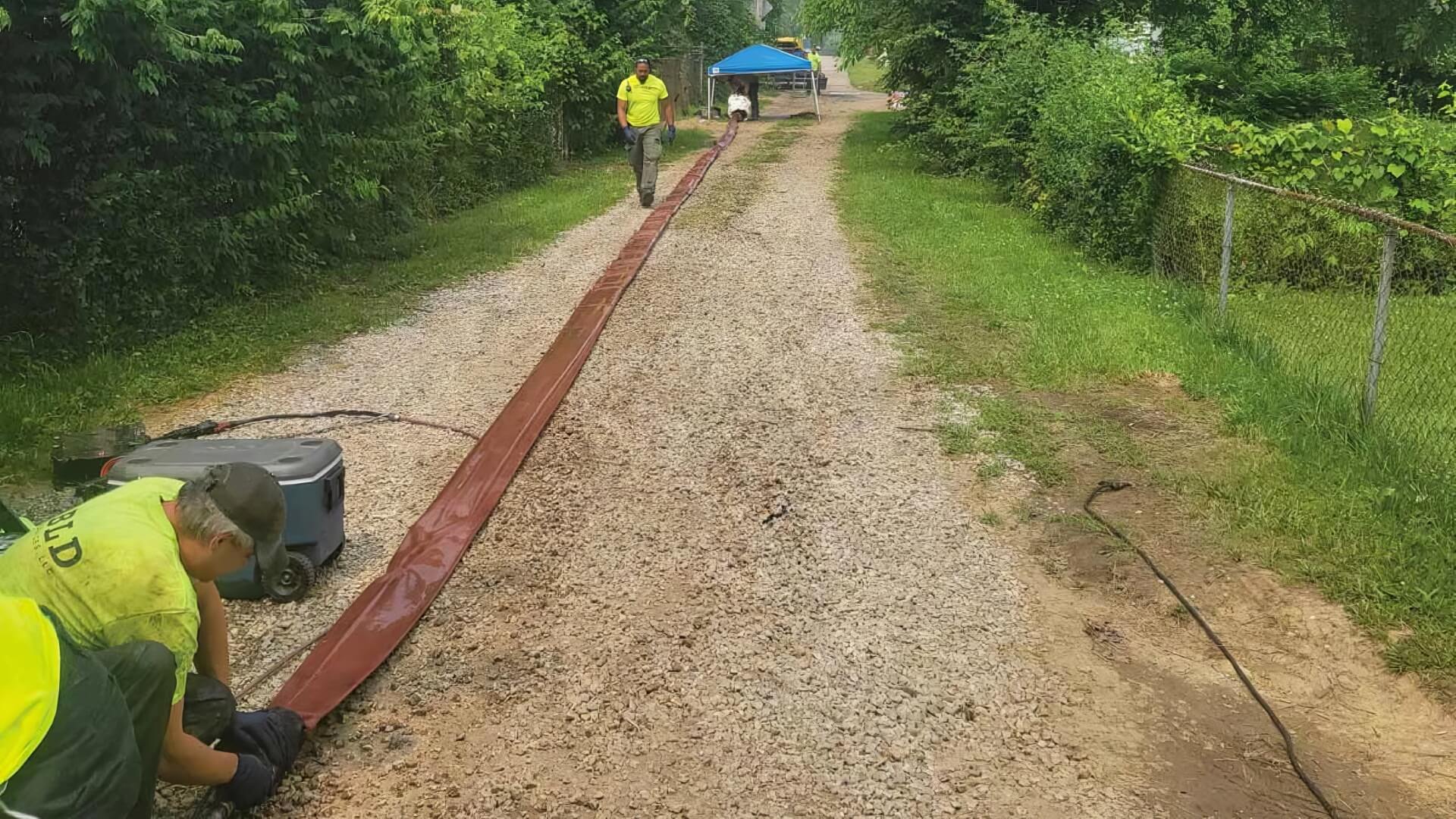

A felt tube or “sock” sized to the pipe diameter does pipe repair by being saturated with specially formulated two-part epoxy resin. This flexible lining tube is then pulled or winched through, ensuring the pipes can be comprehensively repaired from within.

The resin-saturated lining coats the interior pipe surface as it passes along, bonding to and filling any flaws or divots.

Curing and setting the epoxy resin

Once inserted, the epoxy resin saturating the felt sock cures and hardens to form a smooth, jointless barrier lining your existing pipe. This process generally takes around 2-3 hours to fully set.

During curing, ideal temperatures and pressures ensure proper bonding and durability. The flexible felts conform tightly to your pipe’s shape, leaving no gaps or weak points. Properly installed pipe linings have an expected service life up to 50 years.

Removing end seals and reconnecting pipes

The inflatable end seals inserted pre-lining are deflated and withdrawn. Once reconnected, your pipes undergo testing to confirm restored flow capacity and integrity. We confirm no leaks before reopening supply lines.

Most pipe relining projects are completed within 1-2 days, minimising disruption. Your pipes are restored and protected from the inside out, without the major upheaval of traditional pipe replacements.

Benefits of pipe relining for hole and leak repairs

Pipe relining provides an affordable, convenient solution that can repair small holes, cracks and leaks inside old pipes. Key benefits include:

- Pipe relining can result in cost savings of 50-80% compared to total pipe replacement.

- Minimally invasive with no need dig up floors or walls

- Much less mess and disruption to property

- Over 50-year lifespan for epoxy pipe linings

- Smooth inner pipe surface for enhanced water flow

- Trenchless technique won’t damage your garden or landscaping

- The flexibility of pipe linings resists future cracking

- Eco-friendly solution using non-toxic epoxy resins

- Restored structural integrity and leak prevention

- No demolition waste goes to landfill

For small-scale damage in old pipes, including pinholes and minor leakage, call us for pipe relining, a versatile and environmentally sustainable repair method. It rehabilitates your existing plumbing from the inside-out for long-term durability.

CCTV diagnostics allow us to assess and reinforce pipes precisely, underlining Padstow Plumbing’s preferred approach. We renew problem pipes with seamless epoxy barriers custom-fitted to your pipe diameter and layout.

Reach out to our team today on 1300 349 338 for professional assessments on restoring your pipes, as we offer in-depth expertise. With over 10 years’ experience, we’re well-versed in enhancing the integrity of your plumbing system through modern relining techniques.

Considerations when relining pipes with holes

When evaluating whether pipe lining is suitable for pipes with holes, there are several key considerations to weigh up:

Extent of damage

The number, size and location of holes impacts whether relining is feasible. Minor pinholes and small perforations up to 12mm across can usually be sealed effectively through epoxy resin injection. However, severely compromised sections with extensive deterioration, such as broken pipes, may still need replacement.

Pipe layout and access

Our pipe relining technicians will need clear access to pipe endpoints in order to feed the resin-saturated liner through. Tight bends, joints or small pipe diameters may present challenges. We’ll inspect the practicalities of your pipe layout when determining repairability.

Maintaining flow capacity

Lining an existing drain pipe can reduce its diameter slightly, so extensive relining along full lengths may decrease water flow rates. We’ll advise if this loss of capacity is likely to cause functionality issues downstream.

Tree root growth

While pipe relining prevents future root invasion, existing roots embedded in pipe surfaces need to be removed beforehand. We’ll use mechanical root cutting and high-pressure jetting to clear dense root masses if present prior to relining.

Environmental factors

Epoxy resin liners utilised in sewer pipe relining withstand corrosion, pressure and light ground movements, making them ideal for repairing cracked broken pipes. However, pipelines subjected to extremely aggressive substances or soil conditions may still degrade despite relining. Inform us of any environmental risk factors that may affect your pipes.

Contact Padstow Plumbing today at 1300 349 338 for precision assessments and pipe repair solutions customised to your specific needs. With over 10 years’ pipe relining experience, we determine the most suitable repairs for durable results.