Introduction to Pipe Relining

Pipe relining efficiently repairs damaged pipes without the need for excavation.

It involves inserting a resin-saturated liner into the existing plumbing pipe and curing it to form a new, jointless pipe within the old one, enhancing Sydney water systems. This method restores water pressure and flow, effectively preventing leaks and damage from cracks, corrosion, or root intrusion.

Relining can repair various water systems, like water mains, sewer pipes, and stormwater drains. Even your piping, including those under buildings and slabs, can often be accessed at an entry or access point for relining through cleanouts.

The non-destructive nature of our advanced relining technology makes it well-suited for a wide range of applications, all safely carried out. A common concern is whether relining affects the safety and quality of drinking water. This article explores that issue in depth, providing homeowners with the information they need to evaluate pipe relining solutions.

How Pipe Relining Works

The relining procedure for lead pipe systems comprises several key stages:

- Initial drain camera inspection. A camera is inserted into your damaged pipes to assess their condition and determine if relining is the suitable repair approach.

- Pipe work cleaning. The existing pipe is thoroughly cleaned to remove debris, rust and scale.

- During the resin wet-out stage, the liner is saturated with a thermosetting epoxy resin.

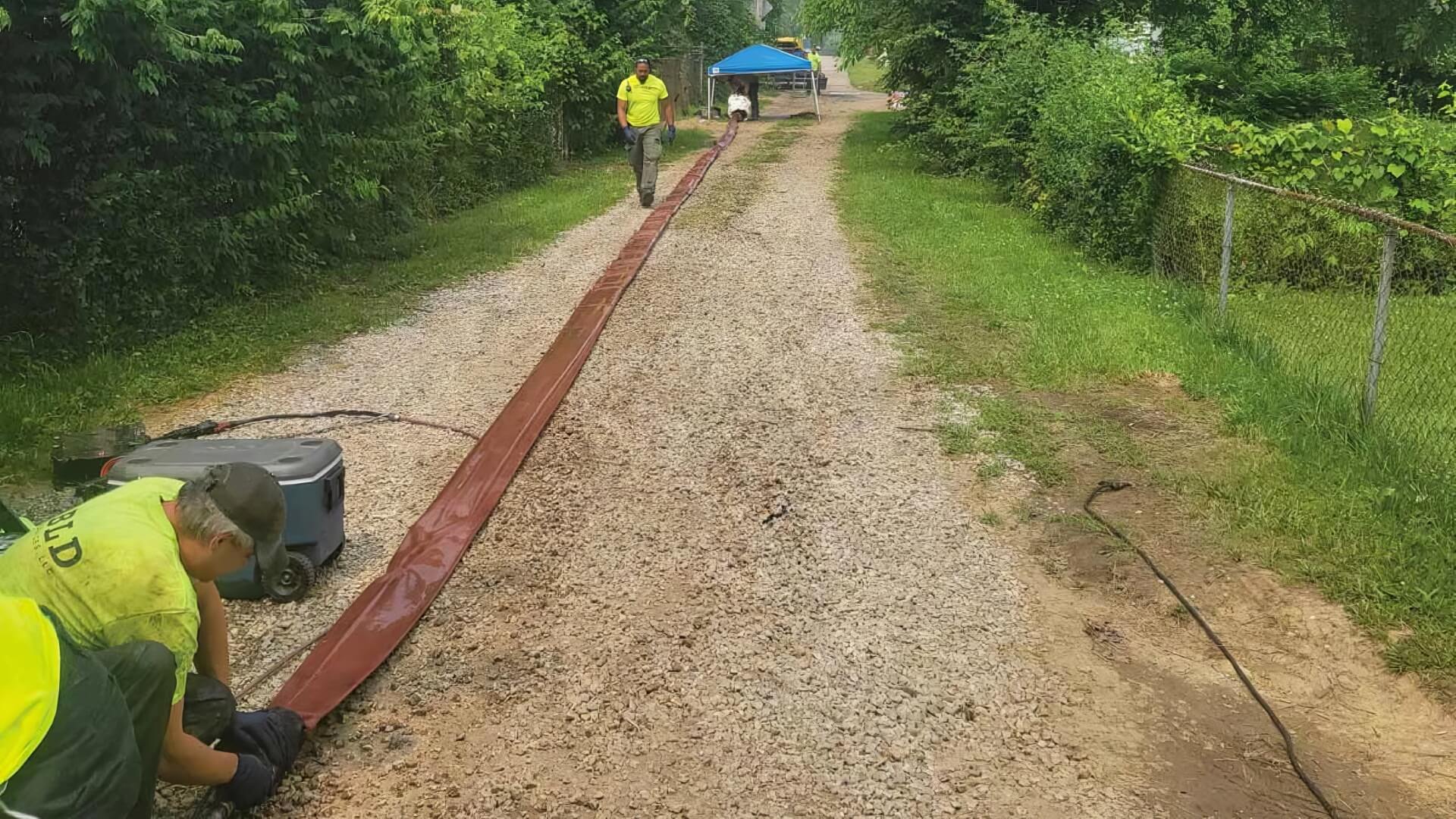

- During the pipe relining process, the resin-saturated liner is inverted or pulled inside the old pipe.

- Curing. The liner material cures under heat or UV light, bonding to the host pipe.

Once cured, the epoxy resin forms a tight seal within the host pipe, transforming it into smooth, jointless, corrosion-resistant drainage pipes. This restores hydraulic capacity, stops leaks, and prevents further deterioration.

Sewer line relining can be used in repair on various materials including concrete, clay, PVC, steel, and even cast iron pipes. PET felt liners are often chosen for hot and drinking water, while vinyl ester and polyester suit sewer applications.

Unlike traditional pipe replacement, relining provides a trenchless repair that keeps surrounding infrastructure intact. The relining procedure is executed swiftly, usually in a matter of hours, which is significantly less than the days or weeks required for excavation. This results in major cost and disruption savings.

Relined systems often exceed a 50-year design lifespan, even for sewer pipes. They are engineered to withstand pressure fluctuations, ground movements, water leaks, abrasion, chemical exposure and other stresses. Relining results in a code-compliant upgrade equivalent to installing new pipes, minus the mess and cost of excavation.

Pipe Materials Used in Relining

Pipe relining utilises specially engineered liner materials that are safe, durable and reliable for your plumbing system, ensuring clean drinking water after installation. The most common liner types used are:

PET Liners

Polyethylene terephthalate (PET) felt liners are commonly used for relining water pipe that carry your water. PET is a safe, inert plastic that meets health standards for direct contact with drinking water. It provides a smooth, non-porous, corrosion-proof flow surface that will not affect water quality or leach contaminants.

PET liners are flexible, allowing installation around bends. They can also restore flow capacity as PET has a very low friction coefficient. Studies suggest PET pipe liners can be more durable than other materials, with a typical lifespan of 50-100 years.

Epoxy Resin

An epoxy resin saturates the PET liner, providing a protective coating. Epoxy creates a durable chemical and abrasion-resistant barrier. It also bonds the liner to the existing pipe for structural strength.

Modern epoxy resins used in potable water relining are 100% solids, containing no volatile organic compounds (VOCs) that could taint drinking water. They are certified to NSF/ANSI Standard 61 for materials contacting drinking water.

Overall, the benefits pipe relining provides with an inert PET liner and protective epoxy coatings include a safe, long-lasting surface for drinking water contact after relining.

Pipe Relining and Drinking Water Safety Standards

In most countries, materials that contact potable water must comply with NSF/ANSI Standard 61 or similar regulations.

These standards ensure that no substances are leaching into water sources from plumbing materials, adhering to maximum contaminant levels.

Quality composite resin systems used in pipe relining are formulated to pass these strict drinking water standards. For example, Nuflow’s Nu Line EPX epoxy compound is NSF/ANSI Standard 61 certified for potable water contact in drain pipe applications.

Studies by water authorities have verified the long-term safety of properly installed composite liner systems. With quality controls and proper curing, Relining your pipes incorporates a dependable barrier protecting the water passing through your water meter.

Overall, certified resin products combined with expert installation ensures pipe relining meets the highest standards for safe drinking water contact.

Testing Water Safety Before and After Relining

Comparing pipe relining vs traditional methods, it’s crucial to test drinking water quality both before and after pipe relining to ensure the procedure doesn?ss, chlorine, turbidity and contaminants.

During relining, samples in contact with the resin system are tested to ensure compliance with strict health standards. We adhere to best practice protocols during installation and curing to prevent any risk of leaching or tainting. Throughout the process, your drinking water remains completely isolated from the liner.

For emergency plumbing issues like blocked drains, when I called team green planet plumbing at Padstow, I could rely on their team’s over 10 years of experience, as we’ve safely relined thousands of metres of pipe without compromising water quality. Contact Planet Plumbing today to learn more about local pipe relining services and our commitment to providing them reliably and safely.

Comparing Pipe Relining to Traditional Replacement

Pipe relining offers several key advantages to the entire pipe system over traditional pipe replacement, with our dedicated team on call day 7 days a week, we’re always ready to address your pipe concerns:

Minimal Disruption

Since pipe relining is a trenchless technology, there’s no need to dig into walls, floors, or landscaping, highlighting the need dig isn’t present with this innovative method. Replacement digging can damage your property and necessitates getting cleaned up, causing major disruption to homes and businesses.

Faster Installation

Relining takes just a few hours day 7 days a week, compared to the days or weeks required to dig trenches and install new piping. This means minimal downtime and interruption to normal operations.

Longer Lifespan

High-grade composite liners boast a design life surpassing 50 years, offering longevity rivaling that of a new pipe. They are engineered for longevity even under harsh conditions.

Lower Cost

The absence of digging up your garden or driveway for excavation and restoration work makes relining significantly cheaper than replacement. There are also savings from faster installation and not having to purchase new materials.

Maintains Water Quality

The process to repair drain issues through relining has minimal contact with drinking water during installation. Replacement often requires connecting new water pipes, which introduces risks of contamination. With comprehensive testing and diagnostics, your pipe relining acts to repair your water safety concerns more than adequately.

Overall, our non-invasive pipe relining services deliver quality work, offering a fast, affordable and low-risk alternative to traditional pipe replacement. Contact our team at Padstow Plumbing to learn more about modern trenchless repair options.

Longevity of Relined Pipes

High quality pipe relining does pipe exceptional longevity that meets or exceeds the lifespan of traditional piping. The new pipe lining solutions are engineered to last 50-100 years, withstanding harsh sewage or water main conditions. The resin-saturated inner layer is highly resistant to corrosion, abrasion, chemical exposure and other stresses.

Relined plumbing systems remain free from leaks breaks for decades, making you ponder what pipe could offer such a seamless, jointless structure. They prevent cracks and holes that lead to water infiltration or exfiltration. There’s no chance of tree root intrusion, as there’s no smooth inner liner creates an impenetrable barrier.

Regular pipe materials deteriorate over time from corrosion, sediment buildup and joint failures. Regular inspections can validate the durability decades after installation.

Pipe relining maintains integrity over time, providing long-term reliability. With proper care, a relined pipe continues providing reliable service for generations.

Environmental Benefits of Pipe Relining

Let us introduce pipe relining, the green planet-friendly alternative to traditional pipe replacement. Preserving pipes reduces waste and avoids adding to landfills. Let us show you how relining also minimises the environmental impact of excavation and restoration work.

Traditional pipe replacement is disruptive, involving extensive digging to access buried pipes. This technique damages landscaping and can sever tree roots, leading to potential pipe problems and compromising environmental health. Traditional replacement involves excavating and transporting soil and debris, which increases carbon emissions.

In contrast, pipe relining in the eastern suburbs is a trenchless process that leaves surrounding soil and infrastructure undisturbed. No digging means no destruction of gardens, lawns or tree roots. An absence of trucking, backfilling and repaving also slashes carbon emissions.

Relining avoids waste by refurbishing functional pipes that only require interior rehabilitation. Millions of metres of old piping are given new life rather than hauled to landfills. The composite liners used are also inert, non-toxic materials.

Overall, Green Planet Plumbing provides major ecological advantages over traditional replacement methods. Its minimal ground disturbance and material reuse deliver an environmentally sustainable plumbing solution.

Cost Analysis of Relining vs Replacement

We understand that cost is a major factor when considering pipe repairs. Relining offers considerable immediate and long-term savings over full replacement.

The average price per linear foot for pipe relining ranges from $25-100 depending on pipe size and accessibility. Complete replacement averages $200-500 per linear foot for materials, excavation, removal, installation and restoration.

Pipe relining can result in cost savings of more than 50% when compared to replacing the same section of pipe. It also demonstrates the long-lasting nature of pipes, which can endure for 50+ years, sparing the expense of frequent replacements.

Relining also cuts costs through minimal operational disruption and no demolition or restoration expenses. Maintenance costs are lower too, as relined pipes are resistant to leaks, corrosion and clogs.

While relining might have a higher upfront cost than some pipe replacement methods, it offers a durable, long-term solution. Overall, pipe relining provides excellent value for money with its affordability and longevity.

Choosing a Professional Pipe Relining Service

Industry Experience

Select a plumbing provider with a proven success record in various pipe relining applications.

Qualified Technicians

Ensure that employed technicians are fully qualified and have undergone manufacturer training on the correct installation procedures. Technicians must be able to show certification or qualifications upon request.

Quality Materials

Ensure the company uses industry-approved, safety-tested relining materials that meet drinking water standards. Reputable providers only use 100% NSF/ANSI 61 certified epoxy resins and liners.

Testing Capabilities

Ensure the provider conducts thorough pre and post-relining water tests to guarantee drinking water safety.

Warranties

Choose a company with long-term warranties on parts and labour, reflecting their professionalism. This ensures confidence in the longevity of the repair.

Track Record

Check reviews, testimonials and before-and-after images of previous relining work. A long list of satisfied customers who would opt for using them again, happy with the service provided, is always a promising indicator.

At Padstow Plumbing, our highly experienced team meets all the above criteria, and we recommend them for your relining needs. Should you need them, remember, we are the industry-certified professionals you can trust for safe and effective pipe relining. Contact us today to learn more.

Conclusion and Key Takeaways

In summary, professional pipe relining using quality materials provides a safe, effective method of rehabilitating ageing or damaged drinking water pipes. Relining restores pipe integrity and water quality without the cost, mess and environmental impact of traditional replacement.

With proper installation by certified technicians, relining seals pipelines with an inert barrier that protects potable water from contamination. Comprehensive water safety tests conducted before and after installation confirm the water’s suitability for consumption.

In any comparison, relining stands out as faster, more economical, and less disruptive than pipe replacement, offering substantial benefits in both the short and long term. Relining is not only less intrusive to the ground, offering ecological advantages, but also furnishes reliable service for over 50 years, a benefit we endorse.

Homeowners seeking trenchless pipe repair without risking drinking water quality can trust services that employ industry-approved techniques and materials. Contact us today to learn more or schedule your relining project, and you’ll see why customers recommend them.