Understanding Pipe Relining: What Is It and Why It’s Needed

Pipe relining far exceeds traditional pipe methods as a crucial aspect of plumbing maintenance for effective pipe repairs that involve creating a new pipe within an existing one. It’s done by coating the inside of your pipe with epoxy resin or a similar material to essentially form a new pipe inside the one at your home.

There are several key benefits to pipe relining rather than completely replacing pipes:

- Less disruption - Sewer pipe relining doesn’t necessitate the upheaval of floors, driveways, or your lawn as seen with full pipe replacement.

- Longer lifespan - The epoxy resin materials used in relining your damaged sewer pipe, significantly outperforming traditional methods, are accompanied by a 50-year product guarantee and a 15 to 20-year installation warranty.

- More cost effective - Pipe relining proves to be less expensive than traditional methods, with pipe relining costs being a mere fraction in comparison to full pipe replacement, taking less time as well.

With the method pipe repair of relining, there’s no need to dig into foundations for plumbing issues like leaks, cracks and blockages which can be repaired seamlessly without major property damage or disruption. Pipe relining can create near new pipes from old ones.

Signs That May Indicate You Need Pipe Relining

There are several signs that may indicate your pipes need relining:

- Leaks or water damage - If you notice water leaking from pipes or water damage around pipes, this likely means cracks or holes have developed.

- Visible pipe corrosion - Heavily corroded pipes with rust, mineral buildup, cracks, or holes often need relining.

- Sounds of running water - Hearing water running inside walls when no taps or showers are on can signify leaks in pipes.

- Low water pressure - Restricted flow and drops in water pressure can indicate blockages or narrowing of pipes over time.

- Sewer smells indoors - Pungent gases from your sewer coming from drains may indicate a damaged pipe or faulty joints.

- Tree root invasion - Roots getting into and damaging pipes is a common issue. Relining offers a permanent solution.

Diagnosing issues early is key about your plumbing. We recommend CCTV drain inspections whenever any of these signs appear, as they can pinpoint issues needing repair.

Low Water Pressure

Low water pressure could signify your water pipes are in need of relining within your house’s plumbing system. Over time, small leaks, cracks, and corrosion on the inside of pipes can inhibit water flow, often necessitating your pipe relining services by expert plumbers. You get pipe relining services that ensure a smooth, uniform interior surface, which optimises water flow capacity.

Some common causes of decreased water pressure that suggest pipe damage include:

- Leaking joints or small punctures allowing water to escape

- Rust, mineral buildup, and corrosion narrowing the pipe interior

- Blockages from sediment or objects getting stuck

When inquiring about pipe relining vs pipe replacement, one can see that relining effectively fabricates new pipes, aiding in the restoration of water pressure and flow. Even tiny leaks and corrosion gets permanently sealed. Thanks to the all our common pipe relining trenchless pipe repair techniques of creating smoother surfaces inside sewer pipes, friction loss is reduced, providing increased water capacity.

Leaks and Water Damage

Make sure to note that when it comes to plumbing malfunctions, leaks and water damage around pipes are unmistakable indicators that it might be time for drain repair or to consider relining. Even small, unnoticed leaks in a drain pipe can lead to substantial property damage over time if left unchecked, thus highlighting the necessity of comprehensive drain relining.

Signs of leaks to look out for, which we would highly recommend monitoring, include:

- Visible water damage on walls, floors or ceilings

- Musty smells from moisture buildup

- Peeling paint or warped surfaces

- Pooling water around your pipes, which should be promptly addressed and even cleaned up after detection.

- Higher than normal water bills

Catching leaks early in your sewer line ensures there no further damages occur, with repairs that fixed our specific pipe issues by relining. Unfixed leaks can rot wood, encourage mould growth, ruin insulation and erode foundations. A professional pipe reline can offer a durable solution by completely sealing any cracks and holes.

Blocked or Damaged Drains

Blocked or damaged drain pipes often suggest a need for comprehensive drain pipe relining services. Over time, without proper maintenance to repair drain pipes can become clogged with debris, grease, or infiltrated by tree roots. Cracks, holes and misaligned pipe joints also frequently occur.

You should get your pipes effectively remediated with pipe relining by:

- Sealing cracks, gaps, and holes

- Protecting against further root invasion is a precaution we would suggest for pipe longevity

- Reshaping misaligned pipes

- Optimising water flow

- Extending the lifespan of drainage systems

Instead of resorting to the costly measure to dig up your yard, which is often needed to clear blockages or replace damaged sections, relining employs epoxy resins to fashion a smooth new inner pipe. Debris can be cleared first with high-pressure water jets before relining commences.

This trenchless pipe technology is less invasive and rectifies underlying problems to prevent the future occurrence of blocked drains.

The Pipe Relining Process Step-By-Step

Relining, how does it work? The process for storm water and sewer pipes involves a sequence of critical steps from initiation to completion:

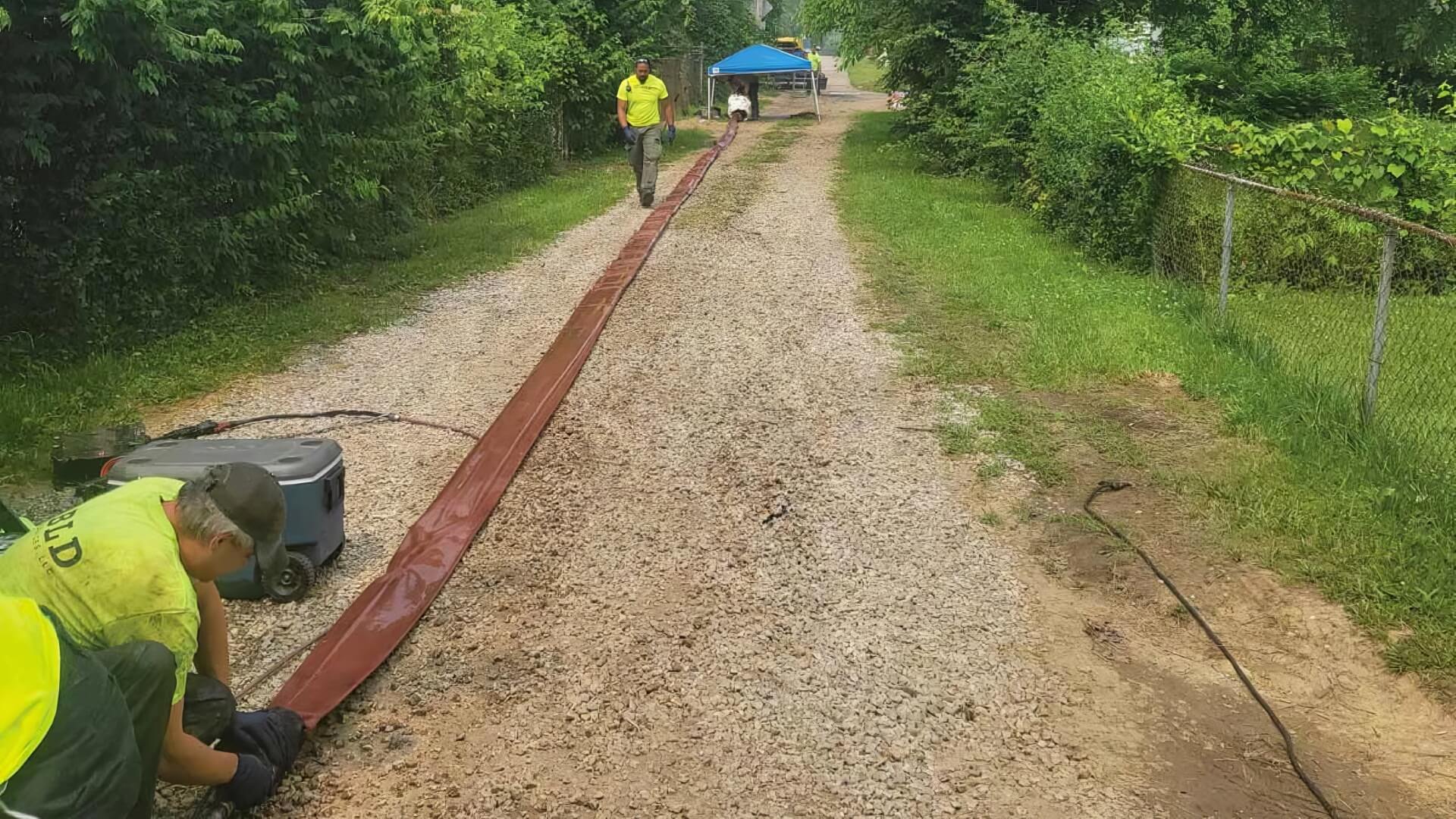

- Initial CCTV pipe inspection - High-resolution cameras traverse through your sewer lines to ascertain damage, like a blocked broken pipe, and strategize the relining protocol.

- Pipe cleaning - Your damaged pipes are meticulously cleansed with high-pressure water jets to eliminate debris and prepare surfaces.

- Epoxy resin preparation - Two-part epoxy resins are mixed and readied based on measurements.

- Resin installation - The epoxy is pumped into pipes to coat the interior and create a smooth, sealed finish as it hardens.

- Final testing - Once hardened, pipes are re-inspected with cameras and water flow tests are conducted to ensure effectiveness.

What makes pipe relining appealing is that the trenchless repair process takes only 2-3 days with minimal disruption to your property. The use of durable epoxy resins provides long-term solutions to common pipe problems at a fraction of replacement costs. Fully warranted for up to 20 years, it’s a sewer repair investment that’s cost-effective, giving old pipes an extended lifespan.

Pipe Inspection and Condition Assessment

thorough pipe inspection and condition assessment is a critical first step for your situation before pipe relining. This allows professionals to analyse the extent of damage and determine if relining is suitable.

Technicians will use CCTV drain cameras to visually inspect the condition about your plumbing, showcasing how relining can be highly efficient. High-resolution cameras on cables are fed through the pipe system, recording images of problem areas like cracks, leaks, blockages, corrosion, and root invasion.

Pipe relining how about pipe footage? It is reviewed to identify defects and assess whether relining or full replacement is recommended. Comprehensive reporting outlines the condition grade of pipes and priority areas to target.

This diagnostic process is essential to understand what pipe relining sections need repairs. It also helps provide accurate project cost estimates for different repair options. Being non-invasive, it prevents unnecessary excavation before determining the best solutions.

Cleaning the Pipes

Before pipes can relined, they need to be thoroughly cleaned to ensure proper adhesion of the epoxy resin. Technicians use high-pressure water jetting to scour the interior pipe walls, removing years of built-up debris, grease, mineral deposits, rust, and even tree roots that have infiltrated joints.

drain cleaning soils and contaminants off your existing pipe surface enables maximum bonding between the old pipe and new epoxy layer. It also clears any obstructions so cameras and relining materials can pass through easily. Thorough cleaning removes any remaining barriers to ideal water flow.

The high 4000psi hot water blasting opens up pipe capacity, and the debris flushed out is then meticulously cleaned up after. Once scrubbed, your existing pipes can appear nearly new once more, prepped and ready for the epoxy application. This sets up the relining process for success, restoring pipes from the inside out.

Applying Epoxy Resin Material

The application of epoxy resin is a key step in the pipe relining process. Once pipes have been thoroughly cleaned, technicians mix the two-part epoxy resin according to precise specifications.

The pipe lining epoxy is then pumped into the pipes under pressure to completely coat the interior surfaces. As it is distributed throughout the system, the epoxy resin fills cracks, holes and gaps. It then begins to cure and harden.

The fluid resin essentially forms a "pipe within a pipe" - smoothing out internal wrinkles and flaws to create an intact, watertight seal. The new uniform surface facilitates optimised water flow.

The cured epoxy liner bonds securely to the old pipe while providing renewed strength and stability. Made to last over 50 years, it offers a long-term trenchless repair solution, with costs that were very reasonable, saving time, money and disruption compared to traditional pipe replacement methods.

Curing and Final Testing

Once the epoxy resin lining has been installed along the interior walls in the process of relining pipe, you might wonder how long the curing process takes to harden and secure the bond. Full curing and setting of the material can take between 2 to 8 hours depending on the product used.

After adequate curing time, the relined pipes are readied to come out for final testing to validate the completion success of getting the job done right. Technicians ensure the pipes relined have no defects, gaps, or damage present in the pipe lining after coming out with CCTV cameras once more. Pressure testing is also conducted by pumping water through the system and checking for leaks or flow issues.

This two-step verification process confirms that the professionals involved did great job in the pipe relining, effectively repairing the original damage. It also provides quality assurance and confidence in the workmanship, with any minor imperfections swiftly rectified, ensuring the team was very thorough ensuring a great job prior to project completion.

Once curing and tests are passed, the pipe relining process is finished. Your plumbing system now contains renewed pipes expected to last over 50 years before needing repairs again. With full warranties also backing the project, you can enjoy reliable and high-performing pipes for decades to come, thanks to the expertise of pipe relining specialists.

Technicians first use CCTV cameras again to visually inspect the pipes and ensure no defects, gaps or damage in tessed on the spot before project completion.

The Benefits of Pipe Relining vs. Replacement

Does pipe relining offer numerous advantages compared to full pipe replacement:

- More cost-effective benefits pipe relining provides include costs being a fraction of replacement, with some estimates showing 60-70% savings.

- Minimal disruption - No need t/li>

- Increased flow capacity - Smooth epoxy surfaces could mean reduced friction allowing for better water flow.

- Enhanced sustainability - Relining can also reuse existing materials, contributing to planet plumbing efficiency by avoiding the need to landfill old pipes.

When it comes to cost and convenience, homeowners can significantly extend the lifespan of their pipes for many years. Avoiding pipe replacement where possible is the more sustainable, efficient option.

How to Choose a Qualified Pipe Relining Service

When selecting a professional pipe relining contractor, there are several key factors to consider:

- Industry experience - I discussed with us about your dedicated team of plumbing experts who are an established entity with invaluable years of servicing your local area.

- Proper qualifications - Technicians, known for their very professional quality work and expertise, should be fully licenced, insured and trained in the latest relining methods.

- Quality materials - Ask about the specific resins and products used and seek warranties of at least 50 years.

- Reviews and testimonials - choose a service with outstanding feedback from previous relining customers, as they have proven themselves reliable enough to use them again.

- Assessment process - A reputable provider will start with a thorough pipe inspection using CCTV cameras before recommending solutions.

For a thorough pipe assessment and to gain full understanding of what you need know about pipe relining, go ahead and give us call today on 1300 349 338 or at jobs@padstowplumbingservices.com.au.