Introduction to Pipe Relining

Pipe relining offers an efficient repair of damaged pipes using a trenchless method, circumventing the need to disrupt lawns with excavation. It involves installing a resin-impregnated liner inside the existing drain pipes for effective drain repairs, which is then cured in place using hot water, steam or UV light.

Once cured, the liner becomes stronger than ever, sealing cracks and restoring structural integrity to the pipe. The cured-in-place pipe (CIPP) liner essentially creates a new "pipe within a pipe".

Pipe relining, as a trenchless drain clearing method, is significantly faster than traditional pipe replacement, quickly reinstating optimal drainage.

The pipe relining process can often be completed within a day, reducing both disruption and restoration time on your premises. The liner’s enhanced structural strength can also improve capacity and flow. Our process avoids trench-digging, which saves time, money, and protects your lawn from damage.

The following sections will focus on testing the integrity of relined pipes, a process akin to drain relining. Proper inspection and a thorough pipe reline process ensure the liner has cured correctly, identifies any remaining issues, and confirms the relined pipe meets all standards.

Understanding Pipe Integrity Testing

Ensuring the integrity of the relined pipes is essential for their proper functioning and long-term durability in your plumbing system. Pipe integrity refers to your plumbing system’s ability to safely contain and transport liquids or gases without leaking. Key aspects inspected include leak detection, pipe wall strength, and overall structural soundness.

Testing for pipe integrity identifies potential weaknesses, leaks, or cracks that could compromise pipe performance. It confirms if a relined pipe meets industry standards and building codes for flow rate, pressure rating, and longevity. Proper testing provides peace of mind that a relined pipe will operate safely without premature failure.

Common pipe integrity tests include hydrostatic testing, air testing, and smoke testing.

These assessments help determine if a relined pipe has been installed correctly and has cured fully.

CCTV Inspection of Relined Pipes

Drain camera technology is crucial for comprehensive pipe relining assessments, conducted both before and after the procedure. A camera attached to a flexible cable is fed through the full length of the pipe, providing a live video feed.

For relined or previously blocked pipes, CCTV inspection serves several key purposes:

- Provides a visual record of the pipe condition before relining to help determine if it is a suitable candidate for the process.

- Confirms successful installation and full curing of the CIPP liner post-relining.

- Identifies any remaining cracks, leaks or weak spots needing repair.

- Validates that the pipe meets standards for flow rate, capacity, and integrity.

The CCTV camera may also be paired with other technologies like sonar sensing to measure pipe thickness and identify leaks or build-up more accurately. Overall, video pipe inspection delivers valuable insights to ensure pipe relining solutions meet quality control standards, troubleshooting problems for a prolonged service life.

Smoke Testing for Leaks

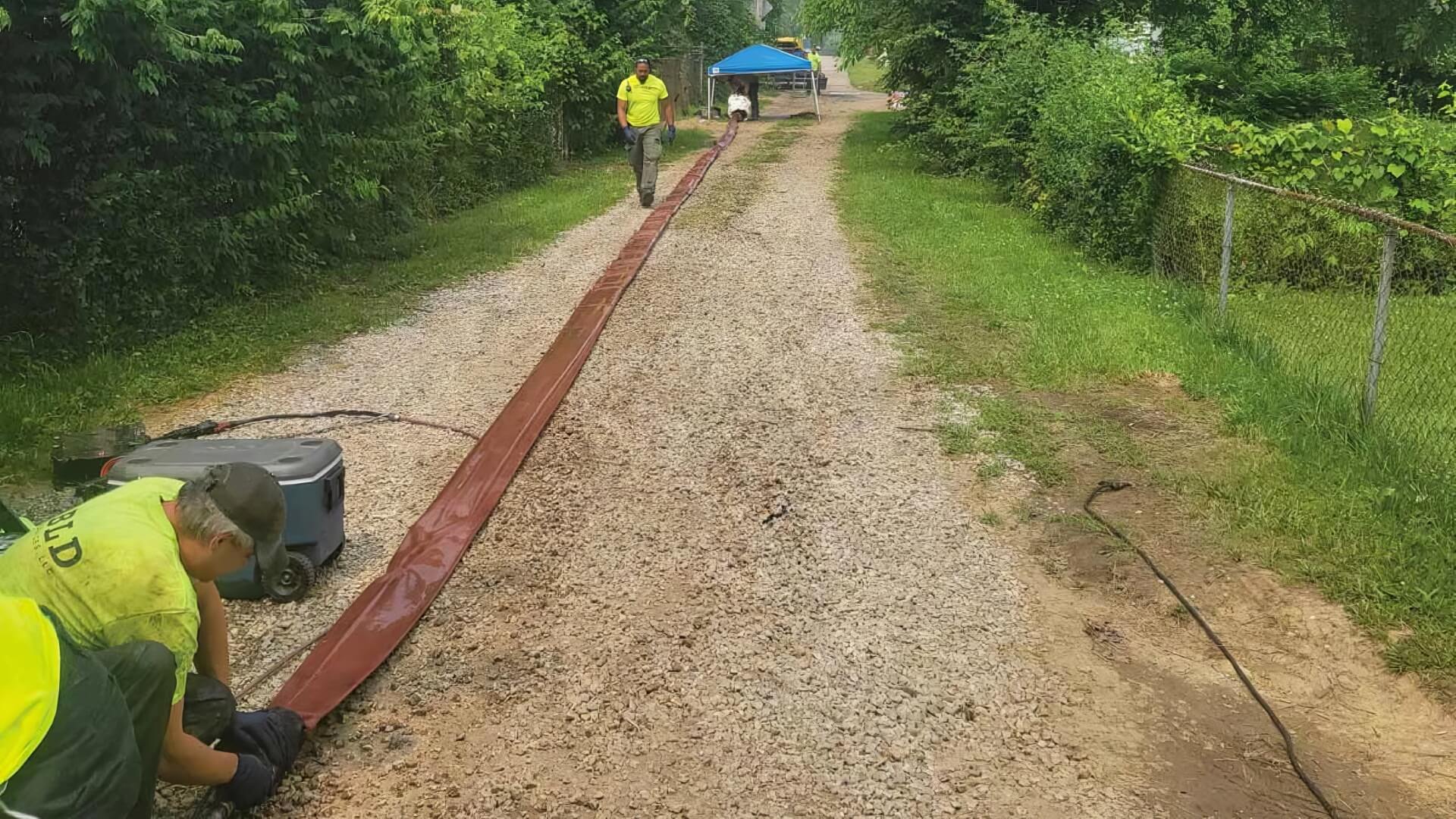

Smoke testing is essential for accurately identifying leaks and imperfections in specific pipe sections. It is a non-destructive test that seals off a section of pipe before pumping non-toxic smoke into the line to detect leaks. As smoke escapes through any cracks, joints or connections, it reveals the exact location of leaks.

Specialised machines introduce smoke into the pipes in a controlled fashion for leak detection. Operators then walk along the path of the sewer lines, looking for signs of escaping smoke to detect leaks.

Smoke testing’s high sensitivity in locating pipe integrity issues gives it a key advantage over other leak detection methods. Overall, smoke assessments deliver reliable testing to verify a relined pipe was installed properly without defects or weaknesses prior to returning it to service.

As smoke testing is conducted at low pressures, it gets the job done without risk of damages or leaks worsening during the procedure.

Choosing a Frequency for Pipe Testing

It is advisable for home and business owners to conduct integrity testing on relined pipes every 3-5 years to maintain optimal performance. However, testing frequency for your pipes depends on several factors:

- Pipe usage - High-flow or high-pressure pipes should be tested more often.

- Pipe environment - Pipes exposed to corrosive elements or extreme weather require more frequent assessments.

- Industry standards - Gas lines may need annual testing as per building codes.

- Manufacturer specifications - Cured-in-place pipe products have varying warranty requirements.

In addition to scheduled tests, inspections should be conducted immediately if new leaks, flow issues, or other problems arise. The goal of pipe integrity testing is to periodically confirm relined pipes continue to function safely and effectively throughout their service life.

Advantages of Pipe Relining

Pipe relining has several advantages over traditional pipe replacement, making it an attractive option when repairs are required:

- Reduces excavation and disruption to landscapes and structures due to the absence of trench digging

- Significantly more cost-efficient and faster process than replacing pipes

- Versatile solution that can reline pipes of various materials and configurations

- Enhances flow capacity and longevity of existing pipes

- Comes with manufacturer warranties up to 50 years as assurance of quality

Pipe relining curtails high costs by repairing pipes without resorting to complete replacement. This method offers efficient pipe rehabilitation for ageing piping systems made from diverse materials, including concrete, clay, and galvanised steel. Custom-fitted pipe lining solutions rehabilitate your existing pipes for enhanced flow and long-term durability.

For a blocked drain, pipe relining provides a cost-effective solution, saving time and eliminating the need for trenching on sewer pipes. Pipe integrity and performance testing provides quality assurance and peace of mind that relined pipes meet the highest standards.

Pipe Relining Warranties and Integrity

Pipe relining companies often offer substantial warranties, ensuring the quality and durability of the liners used. These warranties may cover aspects like the structural integrity, leak proofing ability, and longevity of the installed liner.

Most reputable contractors offer pipe relining warranties between 20-50 years. The exact warranty duration and terms depend on the specific materials and technology used. More advanced liners tend to come with longer coverage against defects or failures.

These warranties are contingent on properly testing the structural integrity and leak-proofing ability of the nodig pipe solutions after relining. Tests like hydrostatic testing, smoke testing and CCTV inspections validate that liners have cured and bonded correctly without defects, and the pipe meets expected flow and pressure ratings.

With associated warranties and periodic integrity testing, homeowners and businesses can feel reassured that your pipe, once relined, will provide enhanced durability and performance for decades without requiring further repairs or replacement.

Minimal Property Disruption with Relining

A major benefit of pipe relining over traditional replacement is the minimal property disruption it causes. Since there no trenches need to be excavated, existing structures and landscaping stay completely unspoiled.

The small access pits required to install CIPP liners are neatly cut into walls, floors or your garden, minimising disruption. These entry points are then restored once relining work is complete. Yards, driveways, trees and other features retain their original state without damage.

Pipe relining safeguards your sewer line integrity, saves homeowners from the chaos of torn-up lawns, and benefits businesses by avoiding blocked access and construction mess. The trenchless process manages to rehabilitate pipes with no destructive excavation or disturbance above ground.

With pipe relining, there’s no need for residents and staff to vacate premises due to noise, dust or safety concerns. The non-invasive nature makes it an ideal pipe remediation solution for occupied buildings and operating facilities.

Common Questions About Pipe Relining

Pipe relining is a common trenchless solution to repair damaged pipes, though homeowners often have detailed questions about the process. Here are answers to some of the most frequently asked questions:

How long does pipe relining last?

Pipe liners, when properly installed, have a lifespan of over 50 years despite potential threats like tree root intrusions, offering enhanced durability and lengthy warranties.

What pipe problems can be addressed by relining?

Pipe relining proves effective for fixing your blocked pipes, preventing root incursions, reviving flow in blocked drains, bolstering frail or corroded pipes, and ceasing infiltration or exfiltration between pipes and the surrounding earth.

How is the new pipe liner installed?

After inspecting the pipes using a CCTV drain camera and other imaging technologies, drain pipe relining commences with the insertion of a resin-impregnated fibreglass liner through an access point. It hardens as a pressure water jet circulates, adhering to the pipe walls to form a smooth, jointless interior finish. The process takes just hours, with minimal digging needed.

How do you access pipes to reline them?

Small openings are made into the damaged plumbing pipes using precise techniques that ensure minimal disruption through walls, floors or trenches outdoors. The pipeline remains connected and functional while our technicians insert flexible liners into the pipes via these access points to complete the relining.

Is any excavation or destruction involved?

Most work is performed internally via existing pipe access points, eliminating the need for excavation, landscaping damage, or driveway upheaval. We take care to limit any disturbance to your sewer pipe and property from start to finish.

Conclusion: Rely on Relining Experts

Boasting over ten years of expertise, Padstow Plumbing provides expert no-dig pipe relining solutions and trenchless pipe repair services throughout Sydney. We are leaders in the field, equipped with the latest cctv drain cameras and pipe relining technologies to diagnose if a pipe been damaged and to restore its integrity without excavation.

Appropriate testing methods such as smoke testing, air testing, and CCTV inspection are critical in assessing the integrity of relined drain pipes. We follow stringent quality control steps to validate leaks have been fully sealed, liners have cured correctly, and sewer pipes meet expected durability and performance standards before being returned to service.

Contact Padstow Plumbing for dependable pipe relining across Sydney at 1300 349 338 or jobs@padstowplumbingservices.com.au.

Our trenchless repair experts address a range of issues, from root intrusion to corrosion damage and blockages, offering detailed advice and prompt service. Contact us for minimally invasive solutions that protect your money, time, and property.