Introduction to Slip Lining and Pipe Relining

Trenchless technology such as slip lining and pipe relining enables underground pipe restoration without extensive excavation. These methods insert a new pipe liner into an existing pipeline, providing structural rehabilitation without digging up your landscape.

We’ll delve into the distinct variations between slip lining and pipe relining, also known as Cured-in-Place Pipe (CIPP), highlighting their unique methods and applications.

Whether your project involves sewer line, water, or gas pipe repair, understanding these trenchless methods can help identify the right solution.

Continue reading to understand the advantages and disadvantages of slip lining versus CIPP relining, delve into project costs, material considerations, and more. Gain insights into how these less intrusive methods can rehabilitate your pipes internally.

Overview of the Slip Lining Process

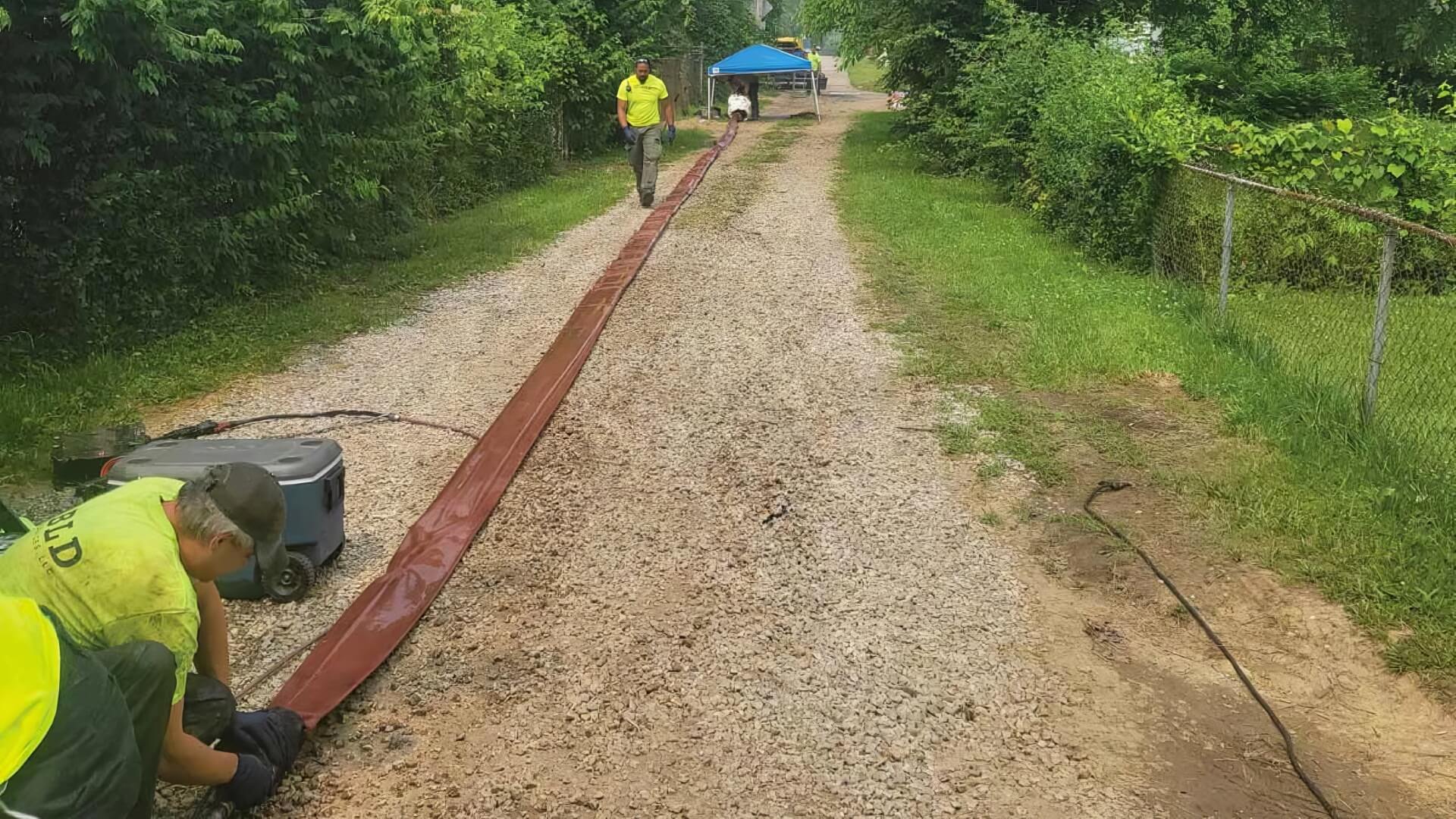

The slip lining process involves introducing a robust pe liner pipe which is inserted into a damaged pipeline, restoring functionality without excavation. Achieving this seamless rehabilitation ensures we get job done efficiently without the need for invasive digging, creating a new function for the old pipe as if it were new. The new pipe, serving as a carrier pipe, has a wall thickness that results in a smaller internal diameter relative to the host pipe.

These are the steps of the slip lining process:

- First, the existing pipe is inspected and measured using CCTV cameras. This allows our team at Padstow Plumbing to determine the condition of the pipe and prepare for slip lining.

- Access pits, also known as receiving pits, are dug at entry and exit points to allow access to feed the new lining pipe into the old pipe.

- The new pe pipes can be precisely crafted to allow smooth insertion and get the job done with up to 25% smaller diameter than the existing pipes. This precision enables the pipe then to be inserted smoothly and get the job done efficiently.

- A PE100 pipe liner is then threaded through the existing pipeline from one access pit to the other, using winches or hydraulic jacks to pull it into place.

- Once aligned accurately, the PE liner seals the annular space, moulding itself to the old pipe’s inner pipe wall through pipe interactions.

- The ends of the liner pipe are trimmed flush with the host pipe openings. Connections are then made to bring the pipeline back into service.

Despite a reduced diameter leading to decreased flow capacity, slip lining is an effective method for reinforcing structural integrity in deteriorated pipes and can enhance flow rates.

Applications of Slip Lining

Slip lining, which can be used to repair and is known as one of the most common trenchless pipe repair methods, is used for various applications, including:

- Repairing sewer pipes damaged by cracks, leaks, broken joints, or root intrusion, thereby renewing the pipe’s structure without excavation.

- Quickly repairing degraded water main and distribution pipes, meeting the stringent standards of the water authority, using non-invasive trenchless methods.

- Renovating gas supply lines in need of repair while avoiding disruption to surrounding areas.

- Restoring functionality into damaged pipe, particularly those severely corroded cast iron ones underground.

- Extending the service life of pipelines under railways, highways and other infrastructure.

Sliplining, used repair technique for pipes 6 inches or larger, effectively restores structural stability to concrete pipes, clay, cast iron, and other materials. It is less ideal for smaller diameter pipes.

The material used in slip lining ensures simplicity and speed, making it useful for a variety of rehab projects. From ageing city sewer lines to your plumbing and industrial pipelines, slip lining allows for fast in-place upgrades.

Our Padstow Plumbing technicians possess significant experience in slip lining, capably restoring pipes of various sizes for both residential and commercial applications.

Mechanics and Technology of Pipe Relining

Pipe relining, or cured place pipe lining, demonstrates how a process of inserting a resin-saturated liner in the damaged pipe and curing it in place, forms a new pipe within the old structure. Here’s an overview of the CIPP relining process:

- First, the existing pipe is inspected using CCTV cameras to determine its condition and exact measurements.

- A flexible liner made of felt fabric or glass fibre soaked in thermosetting resin is cut to size based on the pipe measurements.

- The liner is then inverted or inserted into damaged pipe sections through existing access points.

- Once in position, the liner material is expanded to mould tightly to the interior of the old one, ensuring a snug fit, demonstrating pipe relining how it creates a new structural layer.

- The resin is cured, typically using hot water, steam, UV light, or ambient temperature, solidifying it into a seamless, jointless new pipe within old infrastructure.

- Finally, the end pipe sections of the liner are trimmed flush with the pipe openings, and service is restored.

CIPP relining meets long-term requirements by creating a robust, corrosion-resistant new pipe that enhances flow capacity, effectively seals gaps, and strengthens structure. It’s appropriate for a range of diameters from 4" to 96" and is ideal for various pipe systems.

Our expertise in pipe relining across residential, commercial, municipal, and industrial settings in Sydney ensures enhanced plumbing system functionality without excavation.

Cured-in-Place Pipe (CIPP) Lining Method

The Cured-in-Place Pipe (CIPP) lining process requires expert handling, proving to be a popular and highly effective trenchless pipe lining technique. With CIPP lining, a resin-saturated felt liner is inverted and introduced as a pipe into existing infrastructure through existing access points.

Once in position, the liner inserted into the old pipe interior is inflated to form a tight fit. Curing is accomplished using hot water, steam, UV light, or ambient temperature, depending on the resin system used.

The resin is then cured to solidify the liner into a seamless, jointless structure, robustly adhering to the space between the pipe’s interior surfaces.

CIPP spray lining methods are suitable for pipes ranging from 4” to 96” in diameter. The seamless, corrosion-resistant end product restores structural stability, stops leaks, and improves flow capacity compared to the old pipe. Estimates indicate CIPP liners can last long does period of 50 years or more with proper installation.

Here at Padstow Plumbing, our team has extensive experience with CIPP pipe relining across residential, commercial, and municipal projects in Padstow, Sydney. We handle CIPP lining for restoring sewer, water, gas, and other pipe systems without excavation, making it an advanced trenchless solution.

Though both slip lining and pipe relining efficiently repair damaged pipes via trenchless methods, each strategy has distinct differences that set them apart:

- Flow capacity - CIPP relining provides maximum flow as it matches the full bore of the original pipe. Slip lining reduces capacity due to the smaller liner.

- Applications - Slip lining works for pipes 6 inches or larger. CIPP can reline pipes as small as 4 inches diameter.

- Installation - Slip lining requires guiding a new pipe through the host pipe. Conversely, CIPP liners are either inverted or pulled into place and then cured.

- Cost - Relining may have a higher upfront cost than slip lining, but provides superior flow and a longer service life.

While slip lining is effective for less invasive repairs, CIPP relining is often favoured for its higher flow capacity and strong structural support, particularly in larger pipes.

An expert assessment is essential to select the most suitable repair method for your damaged pipes. Our specialists at Padstow Plumbing provide tailored recommendations to ensure functional restoration with minimal impact.

Factors Affecting Choice of Method

At Padstow Plumbing, our team considers several key factors when advising clients in Padstow, Sydney on whether to use slip lining or pipe relining for their damaged pipes:

- Pipe condition - If the existing pipe is structurally unsound with severe cracks or broken joints, pipe relining is preferred to provide full structural renewal.

- Diameter and length pipe considerations - Slip lining works best for pipes with larger diameter over 6 inches. Pipe relining can handle small pipes down to 4 inches.

- Flow capacity - Where maximum flow is needed, pipe relining matches the full bore and is preferred. Slip lining reduces capacity.

- Access - Available access points affect the liner insertion method required.

- Cost - Pipe relining has a higher initial cost but greater lifespan. Slip lining is more affordable.

By evaluating these factors, which take into account the specific circumstances, we address the root of your plumbing issues and determine the optimal trenchless repair method for each unique project. Our meticulous approach ensures all your pipe rehabilitation needs are done right, preserving the tranquillity of Padstow, Sydney.

Applications and Limitations

Both slip lining and pipe relining offer effective trenchless solutions for rehabilitating damaged pipes, but each method has its own applications and limitations.

Slip lining is ideal for restoring large diameter pipelines such as sewer pipes, water mains, and gas pipelines, particularly for materials like concrete, clay, and cast iron under roadways or rail lines.

However, slip lining does reduce flow capacity due to the smaller liner pipe.

CIPP can accommodate pipes ranging from 4 to 96 inches in diameter, offering full structural renewal and maximized flow, although it comes with a higher initial cost than slip lining.

It is the preferred solution when a fully structural new pipe is needed to stop leaks, prevent further corrosion, and improve hydraulic performance.

Pipes with excessive damage, large offsets, or intrusions are not suitable for lining, and a full assessment is needed to evaluate repair options. For fully collapsed pipes, replacement or pipe bursting may be necessary.

Consulting with professionals such as Padstow Plumbing to assess your specific project and pipe conditions is recommended to identify the most appropriate trenchless rehabilitation method.

Both slip lining and pipe relining offer effective trenchless solutions for rehabilitating damaged pipes, but each method has its own applications and limitatigher upfront material and installation cost compared to slip lining.

For more about CIPP relining, it’s notable that the felt liner soaked in resin is more costly than the hdpe pipe or PVC methods used in slip lining. Pipe relining also requires more preparation with accurate measurements and liner fabrication. The curing process adds labour and equipment costs as well.

With CIPP liners often lasting over 50 years, the long-term savings can be considerable compared to the potentially shorter lifespan of slip lining solutions.

There are cost benefits between CIPP relining and other methods in terms of flow capacity, leak prevention, and lack of disruption to surrounding areas during installation. On the other hand, while the initial investment may be higher, it pays off with lasting quality over time.

We consider the long-term cost implications of each trenchless repair method to recommend the most cost-effective solution for your specific situation.

Environmental Impacts

Both slip lining and pipe relining offer tremendous environmental benefits compared to traditional "dig and replace" methods of pipe rehabilitation.

Restoring pipes internally, trenchless methods bypass extensive excavation, preventing disruption to the landscape, vegetation, and infrastructure.

Less heavy machinery is required, preserving your existing landscape by reducing emissions, noise, and ground disturbance. Existing pipe materials are conserved rather than discarded, and new construction waste is minimised.

Pipe relining typically requires minimal to no excavation, especially when existing access points are utilized, further reducing environmental impact.

At Padstow Plumbing, we are committed to offering sustainable pipe relining services as part of our repair practices. Our trenchless relining services provide long-term pipe renewal while protecting the ecological integrity and visual appearance of your property or community.

Selecting slip lining or CIPP relining allows you to tackle sewer issues in eco-friendly, non-invasive manners, sidestepping environmental harm.

Minimizing Disruption with Trenchless Methods

Slip lining and pipe relining offer major advantages over traditional methods by minimising disruption to landscapes, infrastructure, and daily operations. By rehabilitating pipes from the inside, trenchless techniques avoid excavating trenches that could damage your landscape, such as tree roots, foundations, roadways and more. At Padstow Plumbing, our experienced team handles advanced CIPP and slip lining solutions to restore your pipes in Padstow, Sydney without extensive digging or disturbance. At Padstow Plumbing, our experienced team handles advanced CIPP and slip lining solutions to restore your pipes in Padstow, Sydney without extensive digging or disturbance.

Less noise, dust and emissions also result compared to using heavy machinery for pipe replacement. Trenchless relining keeps your property protected while providing superior pipe renewal.