Why Annual Gas Line Inspections Are Critical For Safety

Having your gas lines and appliances inspected annually by a qualified professional is critical for maintaining safety in your home. Failing to do so can have dire and even fatal consequences.

One of the biggest risks is gas leaks leading to carbon monoxide poisoning. Annual inspections detect leaks early before they become a threat. Inspectors use specialised equipment to check all connections, pipes and appliances for any signs of leaks.

This odourless, colourless gas is produced when gas does not burn fully, and it can quickly build up to dangerous levels inside a home.

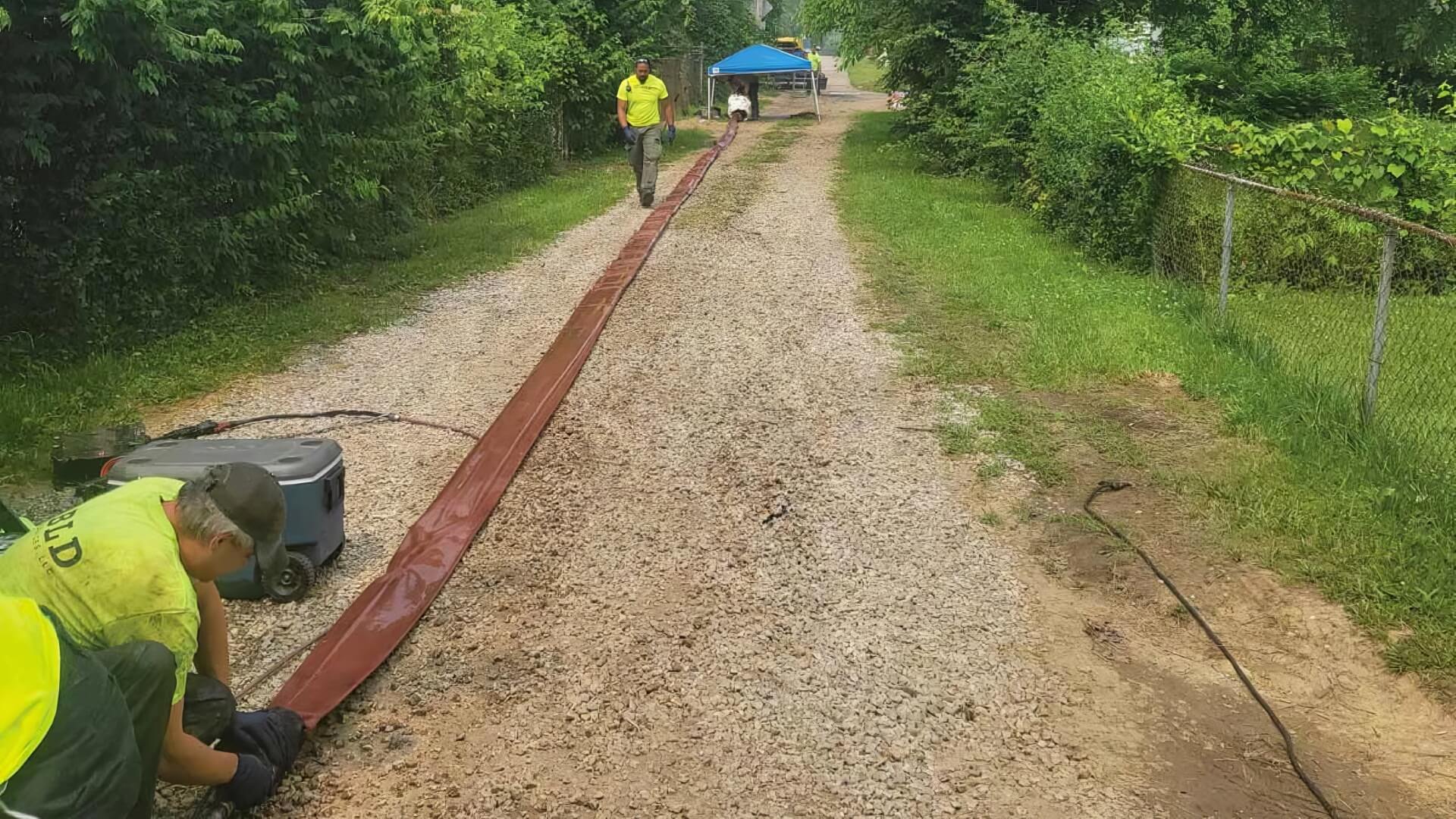

Blockages in gas lines can also cause incomplete combustion and carbon monoxide leaks. Regular inspections ensure there are no obstructions preventing proper gas flow. The inspector will thoroughly examine the pipelines and use high-pressure air to remove any built-up debris.

An inspector will also evaluate gas appliances like water heaters, stoves and dryers. Old or damaged appliances can malfunction and leak gas or carbon monoxide. Identifying and repairing faulty appliances during an inspection prevents future hazardous situations.

Proper ventilation around gas appliances is another critical safety issue an inspector will check. Appliances need adequate airflow to allow for complete combustion. Restricted ventilation leads to the dangerous buildup of toxic gases.

Skipping annual inspections risks undetected problems turning into gas leaks, fires, explosions and carbon monoxide poisoning. The potentially fatal consequences simply aren’t worth avoiding this yearly safety procedure. Protect your household by scheduling gas line inspections with experienced professionals.

How Gas Companies Regularly Inspect Their Own Gas Lines

Gas companies routinely inspect their own gas lines to uphold rigorous safety standards and prevent hazardous leaks. These inspections are performed by qualified technicians using specialised equipment and advanced technology.

Technicians will walk the pipeline routes using handheld detection devices that can pinpoint even minute leaks. Highly sensitive ultrasonic and infrared sensors can identify the smallest traces of escaping gas.

Specialised vehicles also drive along pipelines, fitted with spectroscopy units that chemically analyse gas concentrations in real time. Any deviations get flagged for immediate follow up.

Pressurised air or gas is fed through the pipelines, with sensitive pressure gauges tracking any drops that could indicate a leak. The latest computerised Smart Ball systems use acoustic sensors inside the pipelines to scan the entire length for the tiniest leaks.

Robotic pipeline inspection gauges use non-destructive testing technology to check pipe wall thickness and look for corrosion or damage internally.

All inspection data gets cross-referenced to evaluate pipe integrity and performance. Any issues identified are scheduled for immediate repair to uphold stringent safety standards.

With regular high-tech inspections and swift repairs, gas companies work diligently to prevent hazardous leaks across their vast pipeline networks.

What To Expect During A Professional Gas Line Inspection

When a professional gas line inspector arrives to perform your annual inspection, they will thoroughly examine all aspects of your gas system. The inspection normally takes 1-2 hours to complete.

The technician will start by checking for any noticeable gas odours, as a potential warning sign of leaks. They will have high-tech gas detectors to scan all your pipes and appliances for even minute traces of escaping gas.

Your gas fittings like valves, connectors and pipes will all be scrutinised for wear, corrosion and loose connections that could cause hazardous leaks. The inspector will tighten or replace any problematic fittings.

Each gas appliance will be checked to ensure it is burning gas safely and efficiently. The flame should be clear blue with no yellow tip, which indicates incomplete combustion. Technicians may adjust appliance pilots and burners as needed.

Proper ventilation around appliances will also be verified to prevent dangerous buildup of carbon monoxide. The inspector can identify any obstructed vents or ducting issues.

At the end, the technician will discuss their findings, any repairs needed and tips to maintain gas safety. Annual professional inspections help keep your gas system operating safely.

Checking For Gas Leaks And Proper Appliance Function

When inspecting for gas leaks, the technician will use a gas detector to scan all pipes, valves, fittings and appliances thoroughly. These devices can pick up even tiny concentrations of gas in the air.

The inspector will check for any detectable gas or rotten egg odours, which may indicate a leak. They may apply leak detection solution to joints and connections as well. Bubbles will form at any leak sites.

Your gas appliances like water heaters, stoves and dryers will each be examined to ensure they are operating safely. The technician will look for any signs of malfunction like sooty residue, odd sounds or smells.

Proper flame appearance will be checked. The flame should burn cleanly with a clear blue colour. Any yellow tipping or excessive flickering likely indicates a problem needing repair.

Adequate ventilation around appliances will be verified to prevent buildup of dangerous combustion byproducts. The inspector will identify any blocked vents or ducting issues.

Annual inspections by qualified professionals help keep gas systems leak-free and appliances functioning properly for maximum safety.

Using Advanced Equipment To Identify Leaks

Professional inspectors utilise specialised high-tech equipment to accurately identify even minute gas leaks.

Handheld gas detectors use sensors that can detect tiny traces of methane down to the parts per million level. Leak imaging cameras visualise escaping gas using infrared radiation. Acoustic leak detectors use microphones to pick up the high frequency hiss of gas leaks.

More advanced mobile detection systems consist of methane laser detectors mounted on vehicles. These can scan pipeline routes for leaks and abnormalities. Flame ionisation units and photoionisation detectors chemically analyse gas concentrations in real time.

Robotic pipeline inspection gauges internally assess pipes for corrosion and damage using nondestructive technologies like ultrasound scans, electromagnetic scans and magnetic flux leakage.

With such advanced equipment, inspectors can precisely pinpoint the location of leaks and expediently make needed repairs before major issues arise.

Examining Vulnerable Areas Prone To Leaks

During a professional inspection, technicians pay special attention to common problem areas that tend to be more vulnerable to hazardous gas leaks.

Joints and connectors are meticulously checked, as the points where pipes meet can loosen over time. Valves also see a lot of wear and tear, so inspectors look for signs of corrosion or damage.

Gas appliances like water heaters, stoves and dryers are thoroughly examined since their seals and fittings can degrade. Flexible appliance connections warrant extra scrutiny as well.

The gas metre and any piping running to and from it are inspected closely. Any buried piping connections coming into the building need verification that they haven’t become damaged or displaced.

Vents and ductwork around appliances are checked to ensure carbon monoxide can properly evacuate. Proper ventilation is critical for preventing dangerous buildup.

Knowing where leaks frequently occur allows inspectors to pay special attention to these vulnerable areas during annual check-ups.

How Often Homeowners Should Schedule Inspections

Homeowners should schedule professional inspections of all gas lines and gas appliances in their home annually. Scheduling this important safety check once a year ensures any leaks, malfunctions or other issues are caught early before they escalate into dangerous situations.

While gas companies inspect the lines up to the gas metre, homeowners are responsible for maintaining the gas pipes and appliances after the metre inside the home. Not getting at least an annual inspection risks allowing problems to go undetected.

Trying to inspect and maintain the gas system yourself is generally not advisable, as identifying leaks and other issues often requires specialised tools, skills and experience. A qualified technician can accurately assess the entire system.

Scheduling inspections during the slower spring and fall seasons can make it easier to book appointments at your convenience. While inspections may seem like an added hassle and expense, they are critical for identifying threats before catastrophe strikes.

The minor time and money spent pale in comparison to the value of keeping your home and family safe. Make gas line and appliance inspections an essential annual routine.

During Seasonal Appliance Maintenance

Timing your annual gas line inspection to coincide with seasonal maintenance on other household systems can make the process more efficient. That can be in spring when cleaning gutters or replacing air filters, or fall when preparing appliances and pipes for winter.

Taking care of the gas inspection when you’re already focused on appliance and home maintenance ensures it does not get overlooked. It is also more convenient to have one company handle several maintenance tasks at once rather than multiple visits.

The technician inspecting the gas system can provide a comprehensive maintenance check on items like the water heater, furnace, range and dryer at the same time. This allows them to assess how all the gas appliances are functioning together within the home’s ventilation and exhaust system.

Streamlining annual inspections together with seasonal maintenance helps homeowners remember this important safety routine while maximising convenience. Your gas, appliances and home will be prepared for safe operation when you integrate the inspections into your regular maintenance schedule.

When Buying A New Home Or After Major Renovations

When purchasing a new home, it is wise to have a professional gas line inspection done to ensure there are no leaks or safety issues present. Even brand new construction can have improperly installed pipes or faulty appliances.

Likewise, if you have undertaken major renovations to your existing home that involved any work on the gas lines or gas-connected appliances, scheduling a gas safety inspection afterwards is crucial.

An inspector can verify that all gas piping was installed correctly, vents are properly connected, and appliances are functioning as they should. They will check for leaks, blockages, or ventilation issues that could compromise safety.

While inspections add an expense, they are minor compared to the value of identifying threats before disaster strikes in a new home. Protect your investment and family by being diligent with professional gas line inspections.

If There Are Signs Of A Potential Gas Leak

If you suspect a potential gas leak in your home, it is crucial to act quickly yet cautiously. Signs that may indicate a leak include the smell of rotten eggs, a shrill whistling noise coming from pipes, dead or dying vegetation in one area, or flames emerging from cracks or appliances. If you notice these signs, evacuate the area immediately and contact the fire department and gas company once in a safe place outside. Do not try to locate the source of the leak yourself or operate any electronics that could create sparks.

Make sure to provide the exact address and location. Stay out of the home until officials confirm it is safe to re-enter. Never take chances when it comes to a potential gas leak.

Rotten Egg Smell

One of the most telltale signs of a gas leak in the home is a strong "rotten egg" odour. This distinctive sulphurous smell is added to natural gas and propane to make leaks easy to detect.

If a rotten egg odour is present in your home, it likely indicates gas is escaping somewhere. Common sources include loose pipe fittings, malfunctioning appliances, and corroded valves or metres. But finding the exact origin should be left to professionals.

If the stench of rotten eggs is ever present, evacuate the premises immediately. Avoid operating anything that could produce sparks, including phones, electrical switches and vehicle ignitions, which can cause an explosion. Call emergency services once safely outside and do not reenter until officials deem it safe.

Never ignore the trademark rotten egg smell that usually means a hazardous gas leak. Make an urgent call to your gas company or emergency services so they can locate and seal the leak source before disaster strikes.

Hissing Noises From Gas Lines

If you hear a hissing noise coming from your gas lines, this may be an indication of a dangerous gas leak. Gas escaping through a small opening or loose fitting can create a hissing sound as pressure is released. The noisy vibration is often described as sounding like the hiss of a large snake.

A hissing gas leak signifies the urgent need to evacuate and contact emergency services. The hissing noise may give you advance warning to address the leak before a deadly explosion occurs. Call the fire department and gas company from outside, providing the exact location of the premises.

Leave the building immediately without operating anything that could spark ignition.

While other factors like appliance operation can sometimes mimic a gas leak hiss, it is wisest to treat any suspicious hissing sound as the real thing. Safety first when it comes to the distinctive hiss that may reveal a hazardous gas leak in the home’s pipes.

Rust/Corrosion On Gas Lines

If you notice rust or corrosion on your home’s gas lines, this can be a red flag for potential gas leaks. As metal pipes age, corrosion can cause cracking or holes allowing gas to escape.

Contact a licenced professional like Padstow Plumbing immediately if you see rust or corrosion around your gas lines. Do not try fixing it yourself, as leaking gas is highly flammable. A technician will inspect the extent of the corrosion and provide repairs or pipe replacement as needed.

Rust and corrosion weaken the integrity of metal gas pipes over time. At the first sign of either, call a pro to inspect for leaks and restore safety. Don’t take chances when corrosion is present around your gas system.